|

[CONTACT] Tel: +81 55-933-0007 Email: intl-sales@beatsensing.com Sales reps: Kazuyoshi Morino / Masaru Serizawa

・ Installation does not require a large space (sensor body width is 190 to 250 mm) ・ Having LAN connection accommodates existing system (text commands) ・ It can be used in a dusty environment ・ Users can prepare their own calibration curves (easy-to-use calibration curve preparation software comes with the sensor) ・ Trend of concentration variation, etc. during the process can be viewed (software for continuous recording comes with the sensor) ● Compact Reflective BeatSensor (BS-R1700) long wavelength type component analyzer Best for reflection measurement of granules and powders (high precision type) For low-moisture samples

・ Easy setting (wide measurement distance range of 50~100 mm) ・ Tolerant of variation in concentration distribution (wide measurement spot diameter of φ20) ・ Samples can also be measured through the glass window ● Compact Reflective BeatSensor (BS-R1000) short wavelength type component analyzer Best for reflection measurement of granules and powders (low price type) For high-moisture samples

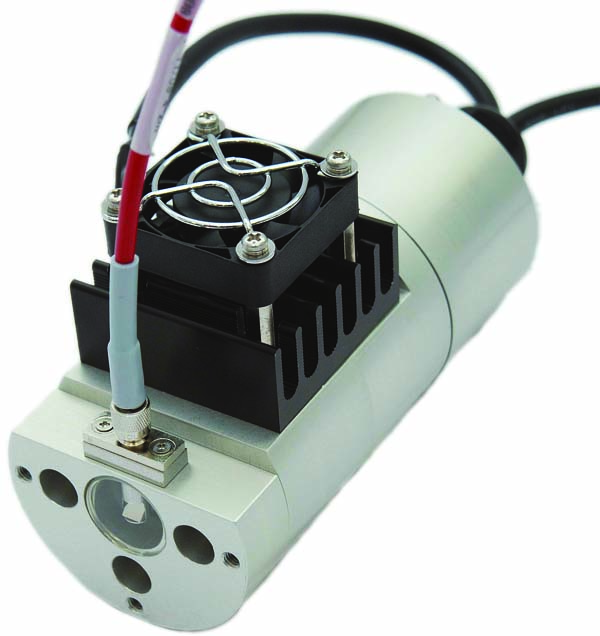

・ Easy setting (wide measurement distance range of 50~100 mm) ・ Tolerant of variation in concentration distribution (wide measurement spot diameter of φ20) ・ Samples can also be measured through the glass window ● Compact Fiber BeatSensor  ・ Two types of sensors to choose from: BS-F1700 long wavelength type component analyzer For low-moisture samples (high precision type) BS-F1000 short wavelength type component analyzer For high-moisture samples (low price type) + Various transmission and reflection probes available to choose from. ↓↓↓ ・ Liquid transmission measurement (batch measurement)  Common cells for analysis Inexpensive glass cells are adequate. Vials with a cap Convenient for storing. ・ Liquid transmission measurement (in-line measurement, flow cell)

Liquid samples are carried through the tube pump Can be used in a lab, or with an existing system. ・ Liquid transmission measurement (in-line measurement, immersion probe)  Can be directly installed into a reaction container or a reactor. ・ Reflection measurement (minute samples)  Optical fiber connection enables the installation in a small space. Close-range measurement (measurement distance of 0~10 mm) MInute samples (small measurement spot diameter of φ3~5) Samples in vials with a cap can be measured. ・ Reflection measurement (high light intensity)  Great when a high light intensity is required. Easy to install (measurement distance of 30~50 mm) Built-in lamp provides bright spot (measurement spot diameter of φ8)

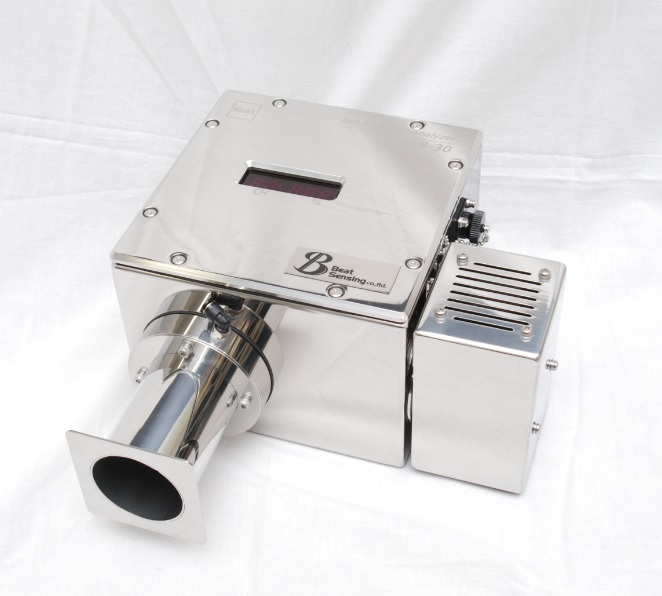

・ Affordable price (design specifically to measure moisture achieved the low price) ・ Users can easily prepare calibration curves on their own(easy-to-use calibration curve preparation software comes with the sensor) ・ Trend of concentration variation, etc. during the process is displayedb (software to record readingsc ontinuously comes with the sensor) ● BGS-30 system Filter spectroscopic moisture analyzer Best for reflection measurement of granules and powders Low/High-moisture filters are available to choose from

・ Easy setting (wide measurement distance range of 230~290 mm) ・ Tolerant of variation in concentration distribution (wide measurement spot diameter of φ25) ・ Samples can also be measured through the glass window

Hydrogen peroxide is said to be the most effective in sterilization/decontamination when it is in the form of gas. NIR VHP MONITOR will help maintain the gas form. ・ Prevention of insufficient input of VHP ・ Prevention of condensation (dew condensation) due to an over-input (condensation causes various adverse effects) ・ Monitoring the concentration of hydrogen peroxide ensures decontamination/sterile condition ● NIR VHP MONITOR

Advantages over electrochemical sensors: ・ Accuracy: calibration curves prepared using the chemical assay values (obtained by impinger) are used for measurement ・ High speed: respond quickly to changing concentrations ・ High concentration: sensor is degradation-free even in a highly concentrated environment ・ Vacuum: usable in a vacuum environment ・ Maintenance: only maintenance required is a wiping of mirror surface even after exposed to condensation About validation of VHP There is no reference gas for VHP, and therefore the validation is difficult on the ground at present. NIR VHP MONITOR therefore is calibrated as follows: ・ NIR device is calibrated according to Japanese Pharmacopoeia and USP1119 ・ For VHP concentration, the calibration curves prepared using the chemical assay values (obtained by impinger) are used ・ For absolute humidity, the calibration curves prepared using the dew-point meter values are used ※ Filter for operational check is included for simple validation. This filter is a stable sample, and therefore always displays the same value. |

Moisture, proteins, lipids, sugars, alcohol, amino acids, active pharmaceutical ingredients, fermentation process, organic synthesis process, VHP, and more: real-time monitoring with NIR sensors

HOME >Products

Copy Right(C)2012 BeatSensing Co., Ltd. All rights reserved.